Understanding Class 1 Fire Rated Acrylic: Safety, Applications, and Benefits

In the world of construction and design, material selection is paramount, and safety is always a top priority. One crucial aspect of material safety is its fire rating. This article delves into the specifics of class 1 fire rated acrylic, exploring its properties, applications, and the benefits it offers compared to other materials. We’ll break down what a class 1 fire rating means, how it’s achieved, and why it’s important for various projects.

What is Class 1 Fire Rated Acrylic?

Class 1 fire rated acrylic is a type of acrylic material that has been treated or manufactured to meet specific fire safety standards. The classification, “Class 1,” refers to its performance in standardized fire tests. These tests measure how quickly a material ignites, how far flames spread across its surface, and how much smoke it generates. Achieving a Class 1 rating signifies that the acrylic has a high level of fire resistance.

Understanding Fire Ratings

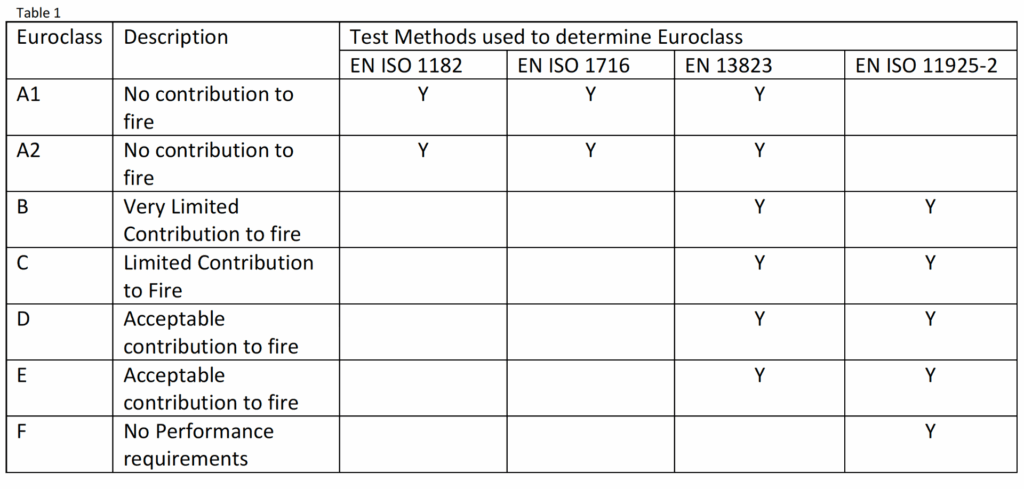

Fire ratings are categorized into different classes, with Class 1 representing a superior level of fire resistance compared to other classes. In the United States, the most common standard is ASTM E-84, also known as the Steiner Tunnel Test. This test measures the flame spread index (FSI) and smoke developed index (SDI) of materials. A class 1 fire rated acrylic typically exhibits a low FSI (0-25) and a low SDI (under 450), indicating it burns slowly and produces minimal smoke.

It’s important to note that different countries and regions may have their own specific fire rating standards. Therefore, when specifying class 1 fire rated acrylic for a project, it’s crucial to verify that the material meets the local building codes and regulations.

How is Class 1 Fire Rated Acrylic Achieved?

The fire-resistant properties of class 1 fire rated acrylic are achieved through various methods, including:

- Adding Flame Retardants: Chemical additives, known as flame retardants, are incorporated into the acrylic polymer during the manufacturing process. These retardants interfere with the combustion process, slowing down the spread of flames.

- Surface Treatments: Some acrylic sheets are treated with fire-resistant coatings that create a protective barrier on the surface. This barrier helps to prevent ignition and limit flame spread.

- Specialized Manufacturing Processes: Certain manufacturing techniques can enhance the inherent fire resistance of acrylic. This may involve modifying the polymer structure or using specific additives that improve its thermal stability.

Applications of Class 1 Fire Rated Acrylic

The enhanced fire resistance of class 1 fire rated acrylic makes it suitable for a wide range of applications where safety is paramount. Here are some common uses:

- Interior Wall Panels: In commercial buildings, hospitals, schools, and other public spaces, class 1 fire rated acrylic is often used for wall panels to enhance fire safety and prevent the rapid spread of flames.

- Signage: Illuminated signs and displays in public areas can pose a fire risk if they are made from flammable materials. Using class 1 fire rated acrylic for signage significantly reduces this risk.

- Lighting Fixtures: Diffusers and covers for lighting fixtures benefit from the use of fire-rated acrylic, especially in environments with stringent fire safety requirements.

- Skylights: While glass is often used, class 1 fire rated acrylic skylights offer an alternative with enhanced impact resistance and fire safety, especially in areas prone to severe weather.

- Protective Barriers: In industries that involve hazardous materials or processes, class 1 fire rated acrylic can be used to create protective barriers that contain potential fires.

- Aircraft Interiors: The aerospace industry requires high safety standards. Class 1 fire rated acrylic is used for interior components to minimize fire risk during flight.

- Marine Applications: Similar to aircraft, marine vessels benefit from fire-resistant materials to protect passengers and crew.

Benefits of Using Class 1 Fire Rated Acrylic

Choosing class 1 fire rated acrylic offers several advantages over standard acrylic or other materials:

- Enhanced Safety: The primary benefit is improved fire safety. By slowing down flame spread and reducing smoke generation, class 1 fire rated acrylic provides valuable time for evacuation and fire suppression.

- Compliance with Building Codes: Many building codes require the use of fire-rated materials in specific applications. Using class 1 fire rated acrylic ensures compliance with these regulations.

- Reduced Insurance Costs: Insurance companies often offer lower premiums for buildings that incorporate fire-resistant materials.

- Durability: Acrylic is known for its durability and resistance to impact, weathering, and UV radiation. Class 1 fire rated acrylic retains these properties while adding fire resistance.

- Design Flexibility: Acrylic can be easily cut, shaped, and molded to create a variety of designs. This allows architects and designers to incorporate fire safety without sacrificing aesthetics.

- Optical Clarity: Acrylic is highly transparent, making it an excellent choice for applications where light transmission is important, such as windows, skylights, and signage.

- Lightweight: Compared to glass, acrylic is significantly lighter, reducing the structural load on buildings.

Comparing Class 1 Fire Rated Acrylic to Other Materials

When selecting materials, it’s essential to consider the fire performance alongside other factors such as cost, durability, and aesthetics. Here’s a comparison of class 1 fire rated acrylic to other common materials:

- Standard Acrylic: Standard acrylic is flammable and does not meet the requirements for Class 1 fire rating. It is not suitable for applications where fire safety is a concern.

- Polycarbonate: Polycarbonate offers good impact resistance and is inherently more fire-resistant than standard acrylic. However, it may not always meet the stringent requirements of Class 1 fire rating without additional treatments.

- Glass: Glass is non-combustible and does not contribute to flame spread. However, it can shatter under high heat, posing a safety risk. Fire-rated glass is available, but it is typically more expensive than class 1 fire rated acrylic.

- Wood: Wood is highly flammable and requires extensive fire-retardant treatments to meet fire safety standards. Even with treatments, wood may not achieve the same level of fire resistance as class 1 fire rated acrylic.

- Metal: Metal is non-combustible, but it can conduct heat and contribute to the spread of fire. Fire-rated metal panels are available, but they can be more expensive and heavier than class 1 fire rated acrylic.

Factors to Consider When Choosing Class 1 Fire Rated Acrylic

When selecting class 1 fire rated acrylic for a project, consider the following factors:

- Fire Rating Certification: Ensure that the acrylic has been tested and certified by a reputable testing laboratory to meet the required fire rating standards (e.g., ASTM E-84).

- Thickness: The thickness of the acrylic sheet can affect its fire resistance. Thicker sheets generally offer better fire protection.

- Optical Properties: Consider the desired level of transparency and light transmission. Some fire-rated acrylics may have slightly reduced clarity compared to standard acrylic.

- UV Resistance: If the acrylic will be exposed to sunlight, choose a product with good UV resistance to prevent yellowing and degradation.

- Impact Resistance: Determine the required level of impact resistance based on the application.

- Cost: Class 1 fire rated acrylic is typically more expensive than standard acrylic. Factor this cost into your budget and compare prices from different suppliers.

- Supplier Reputation: Choose a reputable supplier with a proven track record of providing high-quality fire-rated materials.

Installation and Maintenance

Proper installation and maintenance are essential to ensure the continued fire safety performance of class 1 fire rated acrylic.

Installation

- Follow the manufacturer’s recommendations for installation procedures.

- Use appropriate fasteners and adhesives that are compatible with acrylic and fire-rated materials.

- Ensure that the acrylic sheets are properly sealed to prevent the spread of fire through gaps or cracks.

Maintenance

- Regularly inspect the acrylic sheets for damage, such as cracks or scratches.

- Clean the acrylic with mild soap and water. Avoid using harsh chemicals or abrasive cleaners that could damage the surface.

- Repair any damage promptly to maintain the fire-resistant properties of the acrylic.

Conclusion

Class 1 fire rated acrylic is a versatile and effective material for enhancing fire safety in a wide range of applications. Its combination of fire resistance, durability, design flexibility, and optical clarity makes it an excellent choice for architects, designers, and engineers who prioritize safety and performance. By understanding the properties, applications, and benefits of class 1 fire rated acrylic, you can make informed decisions about material selection and ensure the safety of your projects.

When planning your next project, consider the advantages of using class 1 fire rated acrylic to meet stringent fire safety requirements. Remember to consult with building code officials and fire safety experts to ensure compliance with local regulations.

[See also: Acrylic Sheet Properties and Applications]

[See also: Fire Safety in Building Materials]