Perforated Acrylic Sheet: A Comprehensive Guide

In the world of materials science and design, perforated acrylic sheet stands out as a versatile and aesthetically pleasing option. Its unique combination of transparency, durability, and customizable perforation patterns makes it a popular choice for a wide range of applications. This article will delve into the various aspects of perforated acrylic sheet, exploring its benefits, applications, selection criteria, and more.

What is Perforated Acrylic Sheet?

Perforated acrylic sheet is essentially a sheet of acrylic (also known as polymethyl methacrylate or PMMA) that has been mechanically or laser-cut with a series of holes. These perforations can vary in size, shape, and spacing, allowing for a high degree of customization to meet specific design and functional requirements. Acrylic itself is a thermoplastic known for its clarity, impact resistance (though less than polycarbonate), and weatherability.

Benefits of Using Perforated Acrylic Sheet

The advantages of using perforated acrylic sheet are numerous:

- Aesthetics: The perforations add a unique visual appeal, creating interesting patterns and textures.

- Light Diffusion: The holes can diffuse light, creating a softer, more even illumination.

- Ventilation: Perforations allow for airflow, making it suitable for applications where ventilation is needed.

- Sound Dampening: Depending on the perforation pattern and size, perforated acrylic sheet can help reduce noise levels.

- Weight Reduction: The perforations reduce the overall weight of the sheet, making it easier to handle and install.

- Customization: The perforation pattern can be customized to achieve specific aesthetic or functional goals.

- Durability: Acrylic is a durable material that is resistant to weathering, UV degradation, and impact (to a reasonable extent).

- Transparency: Acrylic retains its transparency, even with perforations, allowing for visibility and light transmission.

Common Applications of Perforated Acrylic Sheet

Perforated acrylic sheet finds applications in a diverse range of industries and projects:

Architectural Design

In architecture, perforated acrylic sheet is used for:

- Facades: Creating visually interesting and functional building facades that provide shade and ventilation.

- Sunshades: Reducing solar heat gain while allowing natural light to enter.

- Interior Partitions: Dividing spaces while maintaining a sense of openness and light.

- Signage: Creating eye-catching and durable signage.

Retail Displays

Retailers use perforated acrylic sheet for:

- Product Displays: Showcasing products in an attractive and functional manner.

- Shelving: Creating lightweight and visually appealing shelving systems.

- Point-of-Sale Displays: Enhancing the visual appeal of point-of-sale areas.

Lighting Fixtures

In lighting, perforated acrylic sheet is used for:

- Light Diffusers: Creating soft and even lighting.

- Lamp Shades: Adding a decorative element to lamps.

- Backlighting Panels: Providing a uniform and visually appealing backlight.

Acoustic Panels

While not as effective as dedicated acoustic materials, perforated acrylic sheet can contribute to sound dampening in:

- Offices: Reducing noise levels in open-plan offices.

- Studios: Improving the acoustics of recording studios.

- Home Theaters: Enhancing the sound quality of home theaters.

Machine Guards

The strength and transparency of perforated acrylic sheet make it suitable for:

- Protecting Workers: Providing a clear barrier while allowing for ventilation and visibility.

Furniture Design

Designers incorporate perforated acrylic sheet into:

- Tables: Creating unique and modern table designs.

- Chairs: Adding a decorative element to chairs.

- Cabinets: Providing ventilation and visual appeal to cabinets.

Factors to Consider When Selecting Perforated Acrylic Sheet

Choosing the right perforated acrylic sheet for your project requires careful consideration of several factors:

Acrylic Thickness

The thickness of the acrylic sheet will affect its strength and rigidity. Thicker sheets are generally more durable and resistant to impact. Common thicknesses range from 1/8 inch to 1/2 inch or more, depending on the application. Consider the structural requirements of your project when selecting the appropriate thickness. For example, a facade panel will likely require a thicker sheet than a decorative display element. [See also: Acrylic Sheet Thickness Guide]

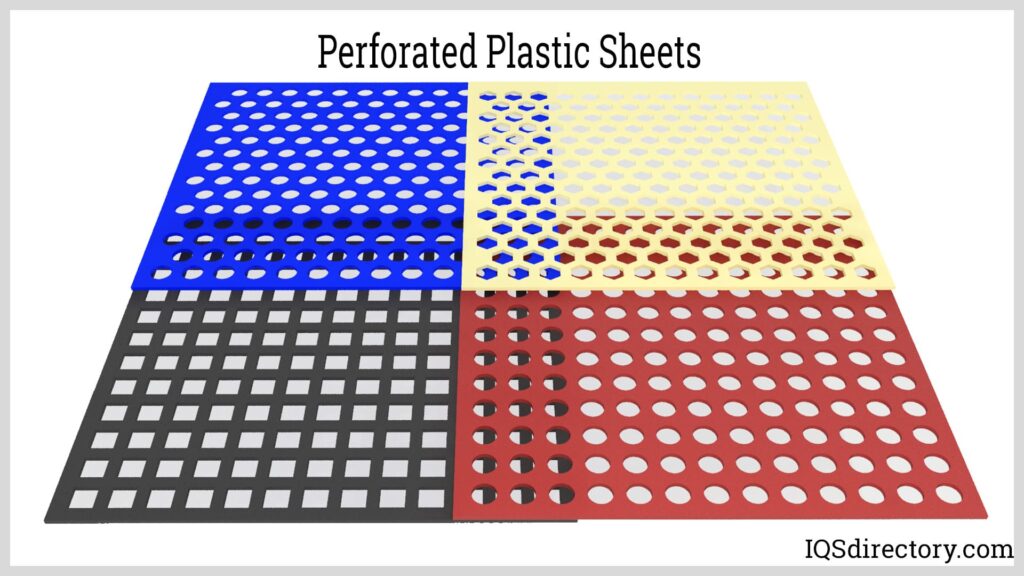

Perforation Pattern

The perforation pattern can significantly impact the aesthetics and functionality of the sheet. Consider the following factors:

- Hole Size: Larger holes will allow for more airflow and light transmission, but may also reduce the sheet’s strength.

- Hole Shape: Round, square, and hexagonal holes are common options, each offering a different visual effect.

- Hole Spacing: Closer spacing will create a denser pattern, while wider spacing will create a more open pattern.

- Overall Pattern: Consider the overall pattern and how it will complement the design of your project. Some common patterns include straight lines, staggered rows, and custom designs.

Acrylic Grade

Different grades of acrylic offer varying levels of clarity, UV resistance, and impact resistance. Cast acrylic is generally considered to be of higher quality than extruded acrylic, offering better optical clarity and resistance to crazing. However, extruded acrylic is often more cost-effective. Consider the specific requirements of your project when selecting the appropriate grade of acrylic. If UV resistance is a major concern, choose a UV-stabilized acrylic sheet.

Color and Finish

Perforated acrylic sheet is available in a wide range of colors and finishes. Clear acrylic is a popular choice for its transparency, but colored acrylic can be used to add a decorative element to your project. Finishes can range from glossy to matte, depending on the desired aesthetic. Consider how the color and finish will complement the surrounding environment and the overall design of your project.

Manufacturing Process

The manufacturing process used to create the perforations can affect the quality and precision of the sheet. Laser cutting is a common method that offers high precision and clean edges. Mechanical drilling is another option, but it may not be as precise. Ensure that the manufacturing process is appropriate for the level of detail required for your project.

Cost

The cost of perforated acrylic sheet will vary depending on the thickness, perforation pattern, acrylic grade, color, and finish. Obtain quotes from multiple suppliers to ensure that you are getting the best possible price. Consider the long-term cost benefits of using a higher-quality acrylic sheet, such as increased durability and reduced maintenance.

Installation and Maintenance

Proper installation and maintenance are essential to ensure the longevity and performance of your perforated acrylic sheet. Follow the manufacturer’s instructions for installation. Use appropriate fasteners and adhesives to secure the sheet in place. Avoid using harsh chemicals or abrasive cleaners, as they can damage the acrylic surface. Clean the sheet regularly with a mild soap and water solution. Inspect the sheet periodically for any signs of damage, such as cracks or scratches. Repair any damage promptly to prevent further deterioration.

Conclusion

Perforated acrylic sheet offers a unique combination of aesthetic appeal, functionality, and durability. Its versatility makes it a popular choice for a wide range of applications, from architectural design to retail displays. By carefully considering the factors outlined in this article, you can select the right perforated acrylic sheet for your project and ensure its long-term performance. The ability to customize the perforation pattern makes perforated acrylic sheet a powerful tool for designers and architects looking to create visually stunning and functional spaces. Whether you need ventilation, light diffusion, or simply a unique aesthetic, perforated acrylic sheet is a material worth considering. Its benefits extend beyond aesthetics, offering practical solutions for various design challenges. Remember to always prioritize safety during installation and maintenance, and consult with professionals when needed. The investment in quality perforated acrylic sheet will undoubtedly enhance the overall value and appeal of your project.