Mastering Chain Link Fence Pipe Connectors: A Comprehensive Guide

Chain link fences are a ubiquitous sight, providing security and demarcation for residential, commercial, and industrial properties. A critical, often overlooked, component of any chain link fence system is the pipe connector. These unassuming fittings play a vital role in ensuring the structural integrity and longevity of the fence. This guide delves into the world of chain link fence pipe connectors, exploring their types, functions, selection criteria, installation best practices, and maintenance tips.

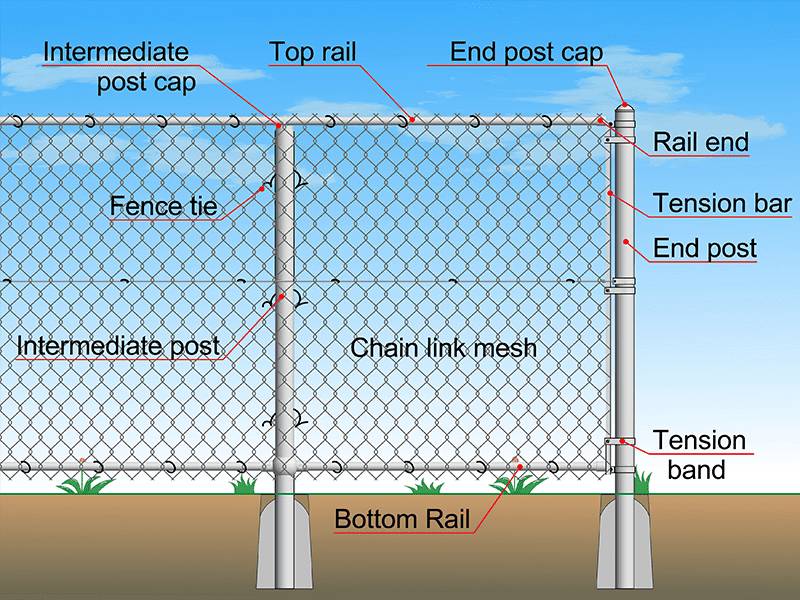

Understanding the Role of Chain Link Fence Pipe Connectors

Chain link fence pipe connectors are designed to join sections of fence pipe together, creating a continuous and robust framework. They come in various shapes, sizes, and materials, each tailored to specific applications within the fence structure. Without proper connectors, a chain link fence would be prone to sagging, instability, and premature failure. The selection of the correct chain link fence pipe connectors is crucial for the fence’s overall performance and durability.

Types of Chain Link Fence Pipe Connectors

Several types of chain link fence pipe connectors are available, each serving a distinct purpose:

- Sleeve Connectors: These are cylindrical fittings that slide over the ends of two pipes, providing a secure connection. They are commonly used for joining line posts or top rails.

- Corner Connectors: Designed for creating 90-degree angles, these connectors are essential for forming corners in the fence line.

- Tee Connectors: These connectors allow for the intersection of three pipes, often used for creating gate supports or adding bracing to the fence.

- End Caps: While not strictly connectors in the sense of joining pipes, end caps are crucial for finishing the ends of pipes, preventing water ingress and corrosion.

- Rail End Cups: Used to connect the top rail to the terminal posts (end, corner, and gate posts).

- Loop Caps: These are used on the top of posts to hold the top rail.

Materials Used in Chain Link Fence Pipe Connectors

The material of a chain link fence pipe connector significantly impacts its strength, corrosion resistance, and lifespan. Common materials include:

- Galvanized Steel: A popular choice due to its strength and resistance to rust. Galvanization involves coating the steel with a layer of zinc, protecting it from corrosion.

- Aluminum: Lighter than steel and naturally resistant to corrosion, aluminum connectors are suitable for coastal environments or applications where weight is a concern.

- Stainless Steel: Offers the highest level of corrosion resistance, making it ideal for harsh environments. However, stainless steel connectors are typically more expensive.

- Powder-Coated Steel: Steel connectors coated with a powder-coated finish provide additional protection against the elements and can be customized to match the fence’s color.

Selecting the Right Chain Link Fence Pipe Connectors

Choosing the appropriate chain link fence pipe connectors involves considering several factors:

Pipe Diameter and Gauge

The connector must be compatible with the diameter and gauge (thickness) of the fence pipe. Using an incorrectly sized connector can compromise the strength of the connection. Measure the outside diameter of your fence pipes accurately to ensure a proper fit.

Environmental Conditions

The climate in your area plays a crucial role in connector selection. In coastal regions with high salt content, stainless steel or aluminum connectors are recommended to prevent corrosion. In areas with heavy snowfall, choose connectors with sufficient strength to withstand the added weight.

Fence Height and Load

Taller fences and those subjected to heavy loads (e.g., from strong winds or climbing plants) require stronger connectors. Consider using connectors made from heavier-gauge steel or reinforced designs.

Aesthetic Considerations

While functionality is paramount, the appearance of the connectors can also be a factor. Choose connectors that complement the overall aesthetic of the fence. Powder-coated connectors offer a range of color options.

Installing Chain Link Fence Pipe Connectors: A Step-by-Step Guide

Proper installation is essential for ensuring the long-term performance of chain link fence pipe connectors. Here’s a general guide:

- Preparation: Gather the necessary tools and materials, including the chain link fence pipe connectors, fence pipes, measuring tape, level, drill (if required), and fasteners (e.g., bolts, screws, or rivets).

- Cutting the Pipes: Cut the fence pipes to the desired length, ensuring clean and square cuts. Use a pipe cutter or a hacksaw for this purpose.

- Fitting the Connectors: Slide the chain link fence pipe connectors onto the ends of the pipes. Ensure a snug fit.

- Securing the Connection: Depending on the type of connector, secure the connection using bolts, screws, or rivets. Drill pilot holes if necessary. Tighten the fasteners securely to prevent slippage.

- Alignment and Leveling: Use a level to ensure that the fence pipes are properly aligned and level. Make any necessary adjustments before fully tightening the connectors.

- Repeat: Repeat steps 3-5 for all remaining connections.

Tips for Successful Installation

- Use the correct tools for the job.

- Follow the manufacturer’s instructions carefully.

- Ensure that all connections are secure and properly aligned.

- Apply a rust-inhibiting coating to the connectors after installation, especially if using galvanized steel.

Maintaining Chain Link Fence Pipe Connectors

Regular maintenance can extend the life of your chain link fence pipe connectors and prevent costly repairs:

- Inspect Regularly: Check the connectors for signs of rust, corrosion, or damage.

- Clean Periodically: Remove dirt, debris, and grime from the connectors using a brush and mild detergent.

- Lubricate Moving Parts: If the fence has gates or other moving parts, lubricate the connectors regularly to prevent seizing.

- Replace Damaged Connectors: Replace any connectors that are severely rusted, corroded, or damaged. [See also: Replacing Fence Posts].

- Touch-Up Paint: If the connectors are painted or powder-coated, touch up any chips or scratches to prevent rust.

Common Problems and Solutions

Even with proper installation and maintenance, problems can sometimes arise with chain link fence pipe connectors:

- Rust and Corrosion: Address rust and corrosion promptly by cleaning the affected area and applying a rust-inhibiting coating. In severe cases, replace the connector.

- Loose Connections: Tighten any loose connections. If the threads are stripped, consider using a larger fastener or replacing the connector.

- Bent or Broken Connectors: Replace bent or broken connectors immediately to prevent further damage to the fence.

The Future of Chain Link Fence Pipe Connectors

The future of chain link fence pipe connectors is likely to see advancements in materials, design, and manufacturing processes. Expect to see more durable and corrosion-resistant materials, such as advanced polymers and alloys. Designs may become more streamlined and aesthetically pleasing. Manufacturing processes may incorporate 3D printing and other advanced techniques to create custom connectors for specific applications.

Conclusion

Chain link fence pipe connectors are indispensable components of any chain link fence system. By understanding their types, functions, selection criteria, installation best practices, and maintenance tips, you can ensure the longevity, stability, and security of your fence. Investing in high-quality connectors and following proper installation and maintenance procedures will pay dividends in the long run, saving you time, money, and hassle. Remember to choose the right chain link fence pipe connectors based on your specific needs and environmental conditions, and always prioritize safety and quality.