Acrylic vs. Resin: Unveiling the Key Differences

In the world of crafting, construction, and even art, acrylic and resin are two materials that frequently pop up. While they might seem similar at first glance, understanding the difference between acrylic and resin is crucial for choosing the right material for your specific project. Both offer unique properties, advantages, and disadvantages. This article delves into the core distinctions between acrylic and resin, exploring their composition, applications, durability, and more. We’ll break down the science and practical applications in a clear, concise manner.

What is Acrylic?

Acrylic is a synthetic polymer known for its clarity, durability, and versatility. Technically, it’s a thermoplastic, meaning it can be repeatedly softened by heating and hardened by cooling. The most common form of acrylic is polymethyl methacrylate (PMMA), often sold under brand names like Plexiglas or Lucite. Acrylic is made from petroleum-derived monomers that undergo polymerization, a process where small molecules (monomers) link together to form a large, chain-like molecule (polymer).

The resulting material is lightweight, impact-resistant (though not shatterproof), and can be easily molded, cut, and shaped. Acrylic’s high transparency makes it an excellent alternative to glass in many applications. Its resistance to weathering also makes it suitable for outdoor use. Understanding the properties of acrylic is key to appreciating the difference between acrylic and resin.

Common Applications of Acrylic

- Signage: Acrylic sheets are widely used for indoor and outdoor signs due to their weather resistance and ability to be easily printed on or illuminated.

- Displays: Point-of-sale displays, museum cases, and retail shelving often utilize acrylic for its clarity and aesthetic appeal.

- Aquariums: Large aquariums often use thick acrylic panels for viewing windows because of their strength and transparency.

- Lenses: Acrylic is used in lenses for eyeglasses, cameras, and other optical devices.

- Automotive: Tail light covers and other automotive components are frequently made from acrylic.

- Art and Crafts: Artists use acrylic paints and mediums, while crafters utilize acrylic sheets for various projects.

What is Resin?

Resin, on the other hand, is a broader term encompassing a wide range of natural and synthetic substances. In the context of crafting and construction, we’re typically referring to synthetic resins. These are thermosetting polymers, meaning they undergo an irreversible chemical change when cured. Once cured, a thermosetting resin cannot be melted or reshaped. Epoxy resin, polyurethane resin, and polyester resin are common types. The key difference between acrylic and resin lies in their curing process and final properties.

Synthetic resins are typically two-part systems, consisting of a resin component and a hardener (or catalyst). When mixed, a chemical reaction occurs, causing the resin to harden into a solid material. The properties of the cured resin depend on the specific type of resin and the hardener used. Resins are generally known for their high strength, chemical resistance, and ability to bond to various materials. Epoxy resin, in particular, is prized for its excellent adhesion and durability.

Common Applications of Resin

- Adhesives: Epoxy resin is a powerful adhesive used in construction, manufacturing, and DIY projects.

- Coatings: Resins are used to create protective coatings for floors, furniture, and other surfaces.

- Composites: Resin is a key component in composite materials like fiberglass and carbon fiber, providing strength and structural integrity.

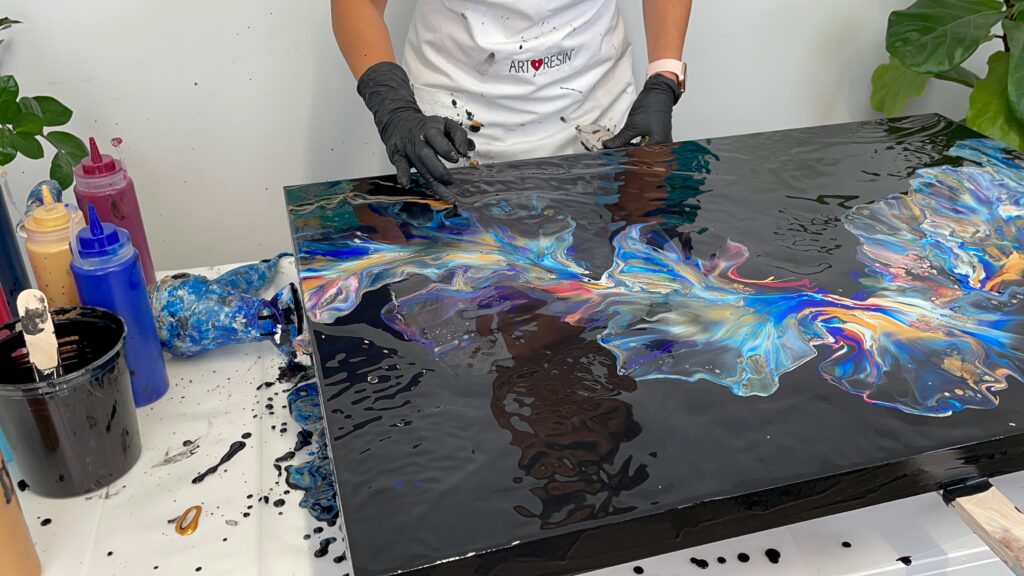

- Jewelry: Resin is used to create unique and colorful jewelry pieces.

- Casting: Resin can be cast into molds to create figurines, sculptures, and other decorative objects.

- Electronics: Epoxy resin is used to encapsulate electronic components, providing protection from moisture and damage.

Key Differences Between Acrylic and Resin: A Detailed Comparison

Now that we’ve defined acrylic and resin, let’s dive into a detailed comparison of their key differences:

Composition and Curing Process

As mentioned earlier, acrylic is a thermoplastic polymer that softens with heat. Resin, specifically synthetic resin, is a thermosetting polymer that undergoes an irreversible chemical change when cured. This is perhaps the most fundamental difference between acrylic and resin. Acrylic doesn’t require a hardener; it simply needs to be heated and cooled. Resin, on the other hand, requires a hardener to initiate the curing process.

Strength and Durability

Resin generally offers higher strength and durability than acrylic, especially epoxy resin. Resin is more resistant to chemicals, solvents, and abrasion. While acrylic is impact-resistant, it can scratch more easily than resin. However, high-impact acrylics do exist and offer improved durability. The choice depends on the specific application and the level of stress the material will be subjected to. Considering the environment where the material will be used is crucial when weighing the difference between acrylic and resin.

Clarity and Transparency

Acrylic is known for its exceptional clarity and transparency, often exceeding that of glass. Resin can also be clear, but the clarity can vary depending on the type of resin and the curing process. Some resins may have a slight yellow tint or become cloudy over time. If optical clarity is paramount, acrylic is generally the better choice. This is why acrylic is preferred for applications like lenses and displays. However, specialized clear casting resins can achieve excellent transparency.

Workability and Ease of Use

Acrylic is generally easier to work with than resin, especially for cutting, shaping, and polishing. It can be easily cut with saws, routers, and lasers. Resin, on the other hand, can be more challenging to work with, requiring careful mixing of the resin and hardener and attention to curing times. However, modern resin formulations and techniques have made it more accessible to hobbyists and DIYers. The learning curve is steeper with resin, but the potential for creating complex and durable objects is greater. Understanding the difference between acrylic and resin in terms of workability is important for project planning.

Cost

The cost of acrylic and resin can vary depending on the specific type, grade, and quantity. Generally, acrylic sheets are more readily available and may be less expensive than specialized resins. However, high-quality casting resins can be quite expensive. It’s important to compare prices from different suppliers and consider the overall cost of the project, including materials, tools, and labor. Sometimes, the initial cost difference between acrylic and resin can be offset by the longevity and durability of the chosen material.

Heat Resistance

Resin, once cured, generally has better heat resistance than acrylic. Acrylic can soften or deform at relatively low temperatures. This is an important consideration for applications where the material will be exposed to high heat. Epoxy resins, in particular, can withstand high temperatures without significant degradation. Always check the manufacturer’s specifications for the maximum operating temperature of the specific acrylic or resin you are using.

UV Resistance

Both acrylic and resin can be susceptible to UV degradation, which can cause yellowing, cracking, and loss of strength. However, UV-resistant formulations are available for both materials. Acrylic is generally more resistant to UV degradation than standard resins. When selecting a material for outdoor use, it’s crucial to choose a UV-resistant grade to ensure longevity. The difference between acrylic and resin in UV resistance can significantly impact the lifespan of your project.

Choosing the Right Material: Acrylic or Resin?

The best choice between acrylic and resin depends entirely on the specific requirements of your project. Here’s a quick guide to help you decide:

- Choose Acrylic if:

- You need high clarity and transparency.

- You need a material that is easy to cut, shape, and polish.

- You need a material that is relatively inexpensive.

- You need a material that is resistant to weathering and UV degradation (choose a UV-resistant grade).

- The application doesn’t require extreme strength or chemical resistance.

- Choose Resin if:

- You need high strength and durability.

- You need a material that is resistant to chemicals, solvents, and abrasion.

- You need a material that can bond to various surfaces.

- You need a material that can be cast into complex shapes.

- Heat resistance is important.

Ultimately, understanding the difference between acrylic and resin empowers you to make informed decisions and select the best material for your needs. Consider the specific properties, advantages, and disadvantages of each material before making your final choice. [See also: Properties of Thermoplastics] [See also: Understanding Epoxy Resin Applications]

Conclusion

Acrylic and resin are both valuable materials with distinct characteristics and applications. While acrylic excels in clarity, ease of use, and weathering resistance, resin offers superior strength, chemical resistance, and bonding capabilities. By carefully considering the key difference between acrylic and resin, you can choose the material that best suits your project’s requirements, ensuring optimal performance and longevity. The world of materials science is constantly evolving, so staying informed about the latest advancements in both acrylic and resin technology is crucial for making the best possible choices. Remember to always prioritize safety and follow manufacturer’s instructions when working with either material.