Acrylic Tube UK: A Comprehensive Guide to Sizes, Applications, and Buying Tips

In the UK, acrylic tubes are versatile materials used across numerous industries, from construction and engineering to arts and crafts. Their clarity, durability, and ease of fabrication make them a preferred choice over glass in many applications. This comprehensive guide explores the various aspects of acrylic tube UK, including sizes, applications, purchasing considerations, and maintenance tips.

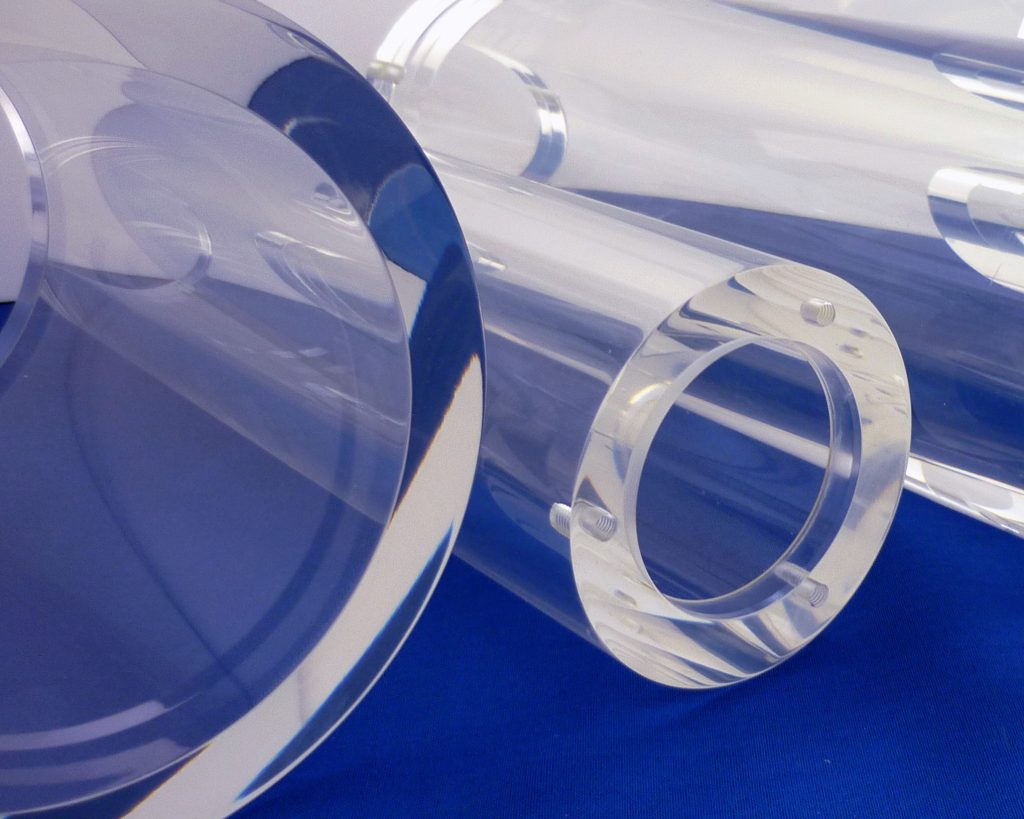

What is an Acrylic Tube?

An acrylic tube, also known as a PMMA (polymethyl methacrylate) tube, is a hollow cylindrical shape made from acrylic plastic. Acrylic is a synthetic polymer known for its transparency, resistance to impact, and weatherability. These properties make acrylic tube UK ideal for both indoor and outdoor use.

Key Properties of Acrylic Tubes

- Transparency: Acrylic offers excellent light transmission, often exceeding that of glass.

- Impact Resistance: It’s significantly more impact-resistant than glass, reducing the risk of shattering.

- Weatherability: Acrylic can withstand prolonged exposure to sunlight, temperature changes, and moisture without significant degradation.

- Lightweight: It’s lighter than glass, making it easier to handle and install.

- Machinability: Acrylic can be easily cut, drilled, and shaped using standard tools.

- Chemical Resistance: It resists many chemicals, but specific resistance varies depending on the chemical.

Common Sizes and Dimensions of Acrylic Tubes in the UK

Acrylic tube UK suppliers offer a wide range of sizes to meet diverse application needs. Dimensions are typically specified by outer diameter (OD), inner diameter (ID), and length.

Standard Sizes

While custom sizes are often available, some standard sizes are commonly stocked. These include:

- Outer Diameter (OD): Ranging from a few millimeters to several hundred millimeters. Popular sizes include 25mm, 50mm, 75mm, 100mm, and 150mm.

- Inner Diameter (ID): Varies depending on the wall thickness. Common wall thicknesses are 2mm, 3mm, 5mm, and 10mm.

- Length: Typically available in lengths of 1 meter, 2 meters, or custom cut lengths.

Custom Sizes

Many suppliers offer custom cutting and fabrication services, allowing you to specify the exact dimensions you need. This is particularly useful for specialized applications where standard sizes won’t suffice. When ordering custom acrylic tube UK, be precise with your measurements to ensure a proper fit.

Applications of Acrylic Tubes in the UK

The versatility of acrylic tubes makes them suitable for a broad spectrum of applications. Here are some common examples:

Architectural and Construction

- Lighting Fixtures: Acrylic tubes are often used as diffusers or covers for LED lighting.

- Handrails and Balustrades: Their strength and transparency make them an attractive option for architectural features.

- Display Cases: Acrylic tubes can create visually appealing display cases for retail environments or museums.

- Structural Components: In certain applications, acrylic tubes can serve as structural elements, especially where transparency is desired.

Industrial Applications

- Fluid Transport: Acrylic tubes can be used to transport liquids and gases in low-pressure applications.

- Level Indicators: They’re often used as sight glasses to visually monitor fluid levels in tanks and vessels.

- Protective Sleeves: Acrylic tubes can protect sensitive equipment from environmental factors.

Arts and Crafts

- Model Making: Acrylic tubes are a popular material for creating scale models and prototypes.

- Aquariums and Terrariums: Smaller diameter tubes are used for decorative features in aquariums and terrariums.

- Jewelry Making: Acrylic tubes can be incorporated into unique jewelry designs.

Point of Sale (POS) Displays

- Product Showcases: Clear acrylic tube UK options are perfect for displaying products in retail settings.

- Signage: Used as structural components or decorative elements in signage.

Factors to Consider When Buying Acrylic Tubes in the UK

Purchasing acrylic tube UK requires careful consideration of several factors to ensure you get the right product for your needs.

Material Quality

Ensure the acrylic tube is made from high-quality PMMA. Look for suppliers that offer certified materials with consistent optical properties and mechanical strength. Recycled acrylic might be cheaper but can have impurities and reduced performance.

Size and Dimensions

Accurately measure the required outer diameter, inner diameter, and length. Consider the wall thickness based on the intended application and the pressure it will need to withstand. Double-check all specifications before placing your order.

Clarity and Transparency

If transparency is important, request samples or detailed product specifications to assess the clarity of the acrylic. Some acrylic tubes may have slight tints or imperfections that could affect light transmission.

UV Resistance

For outdoor applications, choose acrylic tubes with UV resistance. This will prevent yellowing and degradation caused by prolonged exposure to sunlight. Ask your supplier about UV-stabilized options.

Supplier Reputation

Select a reputable supplier with a proven track record of providing high-quality acrylic tube UK products and excellent customer service. Read reviews and check for certifications to ensure reliability.

Price and Lead Time

Compare prices from different suppliers, but don’t compromise on quality for the sake of saving a few pounds. Also, consider the lead time for delivery, especially if you have a tight deadline. Custom sizes may require longer lead times.

Working with Acrylic Tubes: Cutting, Drilling, and Bonding

Acrylic tubes are relatively easy to work with using standard tools, but proper techniques are essential to avoid cracking or damaging the material.

Cutting

Use a fine-toothed saw blade designed for plastics. Support the tube adequately to prevent vibrations. A circular saw, band saw, or even a hand saw can be used. Apply slow, steady pressure to avoid overheating the acrylic.

Drilling

Use drill bits specifically designed for acrylic. Start with a small pilot hole and gradually increase the size. Use a slow drilling speed and apply coolant to prevent the acrylic from melting. Avoid excessive pressure.

Bonding

Use acrylic-specific adhesives for bonding acrylic tube UK. These adhesives create a strong, transparent bond. Clean the surfaces thoroughly before applying the adhesive. Follow the manufacturer’s instructions carefully.

Maintenance and Cleaning of Acrylic Tubes

Proper maintenance will help prolong the life and appearance of your acrylic tubes.

Cleaning

Use a soft cloth and mild soap and water to clean acrylic tubes. Avoid abrasive cleaners or solvents that could scratch or damage the surface. For stubborn stains, use a specialized acrylic cleaner.

Polishing

If the acrylic tube becomes scratched, you can polish it using an acrylic polishing compound and a soft cloth. Apply the compound in a circular motion and buff until the scratches are removed.

Storage

Store acrylic tube UK in a cool, dry place away from direct sunlight and extreme temperatures. Protect the tubes from scratches and impacts during storage.

Finding Suppliers of Acrylic Tubes in the UK

Numerous suppliers in the UK offer a wide range of acrylic tube UK. Here are some ways to find them:

- Online Search: Use search engines like Google to find suppliers in your area.

- Industry Directories: Check online industry directories for listings of plastic suppliers.

- Trade Shows: Attend trade shows related to plastics or construction to meet suppliers in person.

- Referrals: Ask colleagues or industry contacts for referrals to reputable suppliers.

When contacting suppliers, be prepared to provide detailed specifications about the size, quantity, and application of the acrylic tube UK you need. Request quotes from multiple suppliers to compare prices and services.

Conclusion

Acrylic tube UK offers a versatile and durable solution for a wide range of applications. By understanding the properties, sizes, purchasing considerations, and maintenance tips outlined in this guide, you can make informed decisions and ensure you get the right product for your specific needs. Whether you’re working on an architectural project, an industrial application, or a creative craft, acrylic tubes provide a reliable and aesthetically pleasing option. Remember to prioritize quality, accuracy, and reputable suppliers to achieve the best results. [See also: Acrylic Sheet Cutting Guide] Consider the long-term benefits of using high-quality acrylic for your project.